We operate all over the world, and have been in the industry for more than 49 years!

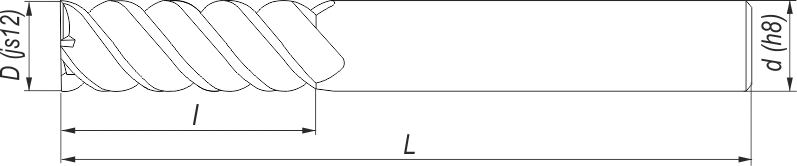

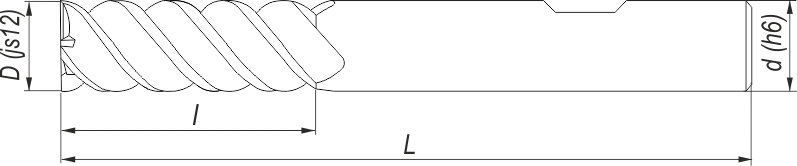

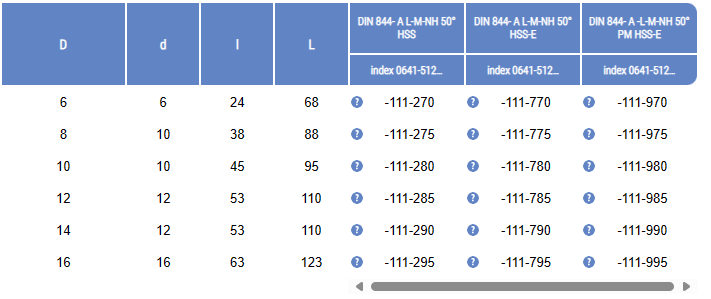

DIN 844- (A,B) L-M-NH 50° End mill, long center-cutting with straight parallel shank

In summary, the DIN 844-(A,B) L-M-NH 50° cutter is a long cutting tool with center blades at 50°, which can be used for deeper cutting and precision surface machining. It is a tool that finds application in machining materials such as wood and plastics, where stability and precision machining are required.

Security policy(edit in Customer Reassurance module)

Delivery rules(edit in Customer Reassurance module)

Return policy(edit in Customer Reassurance module)

Our privacy policy

Our Privacy Policy explains our policies regarding the collection, processing and storage of your data. This policy explains in detail how we use cookies, as well as the options for controlling them.

-

1 What are cookies?

Cookies are small pieces of data, stored in text files that are stored on your computer or other device when websites are loaded in a browser. They are widely used to "remember" you and your preferences, either for a single visit or for multiple repeat visits

-

2 How we use cookies

We use cookies for a number of different purposes. Some cookies are necessary for technical reasons; some enable a personalized experience for both visitors and registered users; and some allow the display of advertising from selected third party networks.

-

3 Cookie control

Visitors may wish to restrict the use of cookies or completely prevent them from being set. If you disable cookies, please be aware that some of the features of our service may not function correctly

-

4 Information We Collect

We only collect information about you if we have a reason to do so-for example, to provide our services, to communicate with you, or to make our services better.

We strive to maintain the trust of visitors to our site. We do not collect, sell, rent or exchange email lists or any data with other companies and businesses. Take a look at our Privacy Policy page to read detailed information about when and why we collect your personal information, how we use it, under what limited conditions we may disclose it to others, and how we keep it secure.

We may change our cookie policy and privacy policy from time to time. This policy is effective as of May 22, 2024.

DIN 844- (A,B) L-M-NH 50° Cylindrical burr, long with central cutting edges with cylindrical shank

|

|

|

|

|

| Multi-blade cutter with countersink on the face | Angle of inclination of the screw line of the chip grooves λ=50° | Directions of the tool's work | Cylindrical shank smooth in accordance with DIN 1835-A | Cylindrical shank smooth in accordance with DIN 1835-B |

|

|

|

|

|

| Spiral-ground blade | Tool made of HSS-E steel | General purpose milling cutters for roughing | Tool made of PM HSS-E steel |

|

|

| Stainless and acid-resistant steels | Stainless and acid-resistant steels with increased chromium and nickel content |

| On special order we make tools with dimensions other than those included in the table. |

The designation DIN 844-(A,B) L-M-NH 50° refers to a specific type of face mill. Here is an explanation of the individual components:

-

DIN 844-(A,B): This is a technical standard that defines the specifications and requirements for burrs. The designation (A,B) may refer to different variants of this standard, which may differ in technical details.

-

L-M-NH 50°:

- L - It means that the cutter has a long shape, which suggests that it is designed for work in areas where deeper cutting is necessary, and with center blades it can also be used for fine machining.

- M - It can refer to other technical characteristics of the cutter, for example, blade geometry or other technical parameters.

- NH 50° - It means that the cutter has center blades at a 50° angle. Center blades are suitable for machining materials such as wood and plastics because they provide stability during machining.

-

Face milling cutter: It is a cutting tool that has blades arranged around the circumference of the wheel (cylindrical) and central blades, which allow precise surface machining. Cylindrical shank ensures stable clamping of the tool in a lathe or other machining equipment.

Specific References

No customer reviews for the moment.