ISO 9 NNWb DIN 4974 pointed boring knife for machining steel and cast iron

ISO 9 NNWb DIN 4974 pointed boring knife is a high-quality cutting tool, ideal for machining steel and cast iron. It is mainly designed for boring pointed holes for precise and efficient material removal in metalworking. Here are some key features of this tool:

1. Precision hole boring: The ISO 9 NNWb DIN 4974 pointed boring knife is specially designed for boring pointed holes. With this tool, high precision and dimensional accuracy can be achieved in workpieces.

2. ISO 9 NNWb DIN 4974 standard: It means that the tool meets strict standards for the geometry and technical parameters of turning knives. This standard guarantees high quality workmanship and efficiency in machining steel and cast iron.

3. Durability and strength: FENES S.A.'s products, which meet ISO 9 NNWb DIN 4974 standards, are characterized by robust construction and high durability. The pointed boring lathe knife can withstand heavy loads and intensive use, resulting in long tool life.

4. Versatility of applications: Although the main purpose of the pointed boring knife is to bore pointed holes, the tool can also be used for other machining operations, making it a versatile tool in the turning workshop.

Pointed boring lathe knife: Choosing excellence in metalworking

This high-quality pointed boring lathe knife is a tool with precise geometry and robust construction that provides reliability, efficiency and excellent results in the metalworking process. With ISO 9 NNWb DIN 4974 standard, this tool meets stringent quality standards, making it an ideal choice for industry professionals.

Precision in every cut

The pointed boring lathe knife is designed for precision and performance. Its pointed blade allows for accurate boring of complex-shaped holes, providing an excellent finish on metal parts. Regardless of the complexity of the task, this tool allows you to achieve excellent results.

Durability and reliability

FENES S.A. products are renowned for their durability and reliability, and the ISO 9 NNWb DIN 4974 pointed boring knife is no exception. Made from the highest quality materials, this tool specialty can withstand heavy loads and intensive use, resulting in long-lasting performance in a variety of industrial applications.

Choose a professional tool from FENES S.A.

When you choose a pointed boring lathe knife from FENES S.A., you are choosing the highest quality, precision and reliability. This is a tool that will allow you to achieve excellent results in steel and cast iron machining, increasing the efficiency and productivity of your industrial operations.

|  |

| For machining steel | For machining cast iron |

|  |  |  |

| Non-alloy steels | Non-alloy and alloy steels | Grey cast iron | Ductile Iron, Malleable Cast Iron |

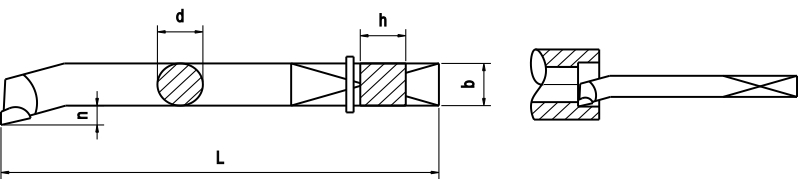

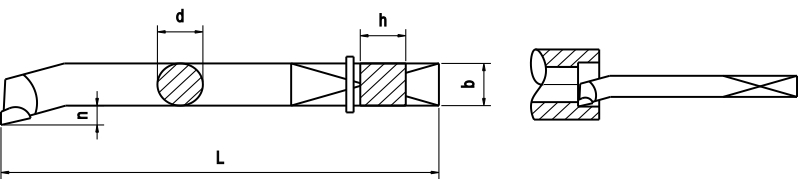

| Size | h | b=b | d | L | n | ISO 9 NNWb

P10 plate | ISO 9 NNWb

P20 plate | ISO 9 NNWb

Plate P30 | ISO 9 NNWb

Plate K10 | ISO 9 NNWb

Plate K20 |

|---|

| index 0641-167 | index 0641-167 | index 0641-167 | index 0641-167 | index 0641-167 |

|---|

| 8 x 8 | 8 | 8 | 8 | 125 | 3 | -100-808* | -200-808 | -300-808* | -400-808* | -500-808* |

| 10 x 10 | 10 | 10 | 10 | 150 | 4 | -101-010* | -201-010 | -301-010 | -401-010* | -501-010 |

| 12 x 12 | 12 | 12 | 12 | 180 | 5 | -101-212* | -201-212 | -301-212 | -401-212* | -501-212 |

| 16 x 16 | 16 | 16 | 16 | 210 | 6 | -101-616* | -201-616 | -301-616 | -401-616* | -501-616 |

| 20 x 20 | 20 | 20 | 20 | 250 | 8 | -102-020* | -202-020 | -302-020 | -402-020* | -502-020 |

| 25 x 25 | 25 | 25 | 25 | 300 | 10 | -102-525* | -202-525 | -302-525 | -402-525* | -502-525 |

| 32 x 32 | 32 | 32 | 32 | 355 | 12 | -103-232* | -203-232 | -303-232* | -403-232* | -503-232* |

| * on special order (lead time approx.3 weeks). |

| All knives are also available in a left-hand version by special order. |

The ISO 9 NNWb DIN 4974 designation refers to a standard and technical norm for turning knives. Here is an interpretation of the various elements of this designation:

1. ISO 9: Denotes a standard for turning knife geometry. ISO (International Organization for Standardization) standards specify geometric and design parameters for cutting tools, including turning knives, to ensure their standardization and compatibility in various industrial applications.

2. NNWb: Denotes the detailed geometric parameters of a lathe knife, such as rake angle, cutting angle, corner radius, etc. These parameters are determined in accordance with standards and norms to ensure proper functionality and performance of the tool in various applications.

3. DIN 4974: Denotes the German technical standard for turning knives. This standard specifies requirements for the design, tolerances and markings of turning knives, with the aim of ensuring their quality, durability and compliance with international standards.

In summary, the ISO 9 NNWb DIN 4974 designation is a turning knife geometry standard that specifies the detailed geometric parameters of the tool, according to the German technical standard, to ensure its quality and functionality in metalworking.

Security policy(edit in Customer Reassurance module)

Delivery rules(edit in Customer Reassurance module)

Return policy(edit in Customer Reassurance module)