We operate all over the world, and have been in the industry for more than 49 years!

Twist drill bit with parallel shank DIN 6537 grinded

Do you need a drill bit for machining steel, cast iron, aluminum or plastics? Wondering which drill bit will work best for you? Discover how to choose the perfect tool for your needs in our guide.

Security policy(edit in Customer Reassurance module)

Delivery rules(edit in Customer Reassurance module)

Return policy(edit in Customer Reassurance module)

Our privacy policy

Our Privacy Policy explains our policies regarding the collection, processing and storage of your data. This policy explains in detail how we use cookies, as well as the options for controlling them.

-

1 What are cookies?

Cookies are small pieces of data, stored in text files that are stored on your computer or other device when websites are loaded in a browser. They are widely used to "remember" you and your preferences, either for a single visit or for multiple repeat visits

-

2 How we use cookies

We use cookies for a number of different purposes. Some cookies are necessary for technical reasons; some enable a personalized experience for both visitors and registered users; and some allow the display of advertising from selected third party networks.

-

3 Cookie control

Visitors may wish to restrict the use of cookies or completely prevent them from being set. If you disable cookies, please be aware that some of the features of our service may not function correctly

-

4 Information We Collect

We only collect information about you if we have a reason to do so-for example, to provide our services, to communicate with you, or to make our services better.

We strive to maintain the trust of visitors to our site. We do not collect, sell, rent or exchange email lists or any data with other companies and businesses. Take a look at our Privacy Policy page to read detailed information about when and why we collect your personal information, how we use it, under what limited conditions we may disclose it to others, and how we keep it secure.

We may change our cookie policy and privacy policy from time to time. This policy is effective as of May 22, 2024.

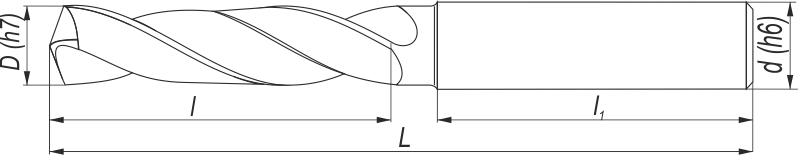

Ground twist drill bit with DIN 6537 cylindrical shank for machining steel, cast iron, aluminum and plastics

Ground twist drills with DIN 6537 cylindrical shank are advanced tools used for precision drilling of holes in various materials, especially metals. The DIN 6537 cylindrical shank is a standard type of shank, which is characterized by a cylindrical shape that allows the drill bit to be easily and stably clamped in the tool holder.

These drill bits are carefully ground to ensure sharp and precise cutting edges. This makes drilling smooth and trouble-free, and the resulting holes are clean and accurate. The DIN 6537 standard specifies the drill's dimensions, tolerances and other technical parameters, ensuring consistency and compliance with industry standards.

DIN 6537 cylindrical shank ground twist drills are widely used in the metalworking industry, construction, machine manufacturing, as well as in craft and repair shops. They can be used for drilling holes of various diameters and depths in metals, steel, aluminum, as well as other materials.

In short, DIN 6537 cylindrical shank ground twist drills are a reliable tool that provides high precision and efficiency in the process of drilling holes in various materials. Thanks to their high quality workmanship and compliance with DIN standards, they are an excellent choice for professionals and hobbyists involved in metalworking.

|

|

|

|

|

|

| Recommended drilling depth | Drill tip angle | Drill 2-cut 2-flute drill bit | Cylindrical shank smooth in accordance with DIN 6535-HA | Solid carbide tool | Coating on the cutting part |

|

|

|

|

|

| Non-alloy steels | Non-alloy and alloy steels | Stainless and acid-resistant steels | Stainless and acid-resistant steels with increased chromium and nickel content | Cast Iron Gray |

|

|

|

|

|

| Ductile Iron, Malleable Cast Iron | Titan | Aluminum, copper | Aluminum alloys, copper alloys | Plastics |

| D | d | I1 | L | I | Drilling depth: 3xD | |

|---|---|---|---|---|---|---|

| index 0641-498-000 |

tiAIN index 0641-498-040 |

|||||

| 4 | 6 | 36 | 66 | 17 | -020 | -020 |

| 5 | 6 | 36 | 66 | 20 | -025 | -025 |

| 6 | 6 | 36 | 66 | 20 | -030 | -030 |

| 7 | 8 | 36 | 79 | 29 | -035 | -035 |

| 8 | 8 | 36 | 79 | 29 | -040 | -040 |

| 9 | 10 | 40 | 89 | 35 | -045 | -045 |

| 10 | 10 | 40 | 89 | 35 | -050 | -050 |

| 11 | 12 | 45 | 102 | 40 | -055 | -055 |

| 12 | 12 | 45 | 102 | 40 | -060 | -060 |

| 13 | 14 | 45 | 107 | 43 | -065 | -065 |

| 14 | 14 | 45 | 107 | 43 | -070 | -070 |

| 15 | 16 | 48 | 115 | 45 | -075 | -075 |

| 16 | 16 | 48 | 115 | 45 | -080 | -080 |

| 17 | 18 | 48 | 123 | 51 | -085 | -085 |

| 18 | 18 | 48 | 123 | 51 | -090 | -090 |

| 19 | 20 | 50 | 131 | 55 | -095 | -095 |

| 20 | 20 | 50 | 131 | 55 | -100 | -100 |

| D | d | I1 | L | I | Drilling depth: 5xD | |

|---|---|---|---|---|---|---|

| index 0641-498-000 |

tiAIN index 0641-498-040 |

|||||

| 4 | 6 | 36 | 74 | 29 | -220 | -220 |

| 5 | 6 | 36 | 82 | 35 | -225 | -225 |

| 6 | 6 | 36 | 82 | 35 | -230 | -230 |

| 7 | 8 | 36 | 91 | 43 | -235 | -235 |

| 8 | 8 | 36 | 91 | 43 | -240 | -240 |

| 9 | 10 | 40 | 103 | 49 | -245 | -245 |

| 10 | 10 | 40 | 103 | 49 | -250 | -250 |

| 11 | 12 | 45 | 118 | 56 | -255 | -255 |

| 12 | 12 | 45 | 118 | 56 | -260 | -260 |

| 13 | 14 | 45 | 124 | 60 | -265 | -265 |

| 14 | 14 | 45 | 124 | 60 | -270 | -270 |

| 15 | 16 | 48 | 133 | 63 | -275 | -275 |

| 16 | 16 | 48 | 133 | 63 | -280 | -280 |

| 17 | 18 | 48 | 143 | 71 | -285 | -285 |

| 18 | 18 | 48 | 143 | 71 | -290 | -290 |

| 19 | 20 | 50 | 153 | 77 | -295 | -295 |

| 20 | 20 | 50 | 153 | 77 | -300 | -300 |

| On special order we make tools with dimensions other than those included in the table |

Here is an elaboration of the parameters of this drill:

1. Recommended drilling depth: This is the maximum depth to which it is recommended to drill with a given drill bit. This includes both the technical limitations of the tool and optimal machining results.

2. Drill tip angle: This is the angle at which the drill blades are made. This angle is crucial to the effectiveness of drilling in various materials. A proper tip angle helps minimize friction and provides better guidance for the drill bit, which translates into efficiency and precision in the drilling process.

3. 2-Cutting-Blade Drill 2-Slot*: The term "2-blade" means that the drill has two cutting blades. The number of blades affects the speed of drilling and the quality of the hole. "2-blade" suggests the presence of two counter-directional bald spots (thin elongation strips) that help evacuate chips and cool the blades.

4. Smooth cylindrical shank according to DIN 6535-HA: This is a standard cylindrical shank that meets the specified DIN 6535-HA standards. It is a cylindrical shank that provides stable clamping of the drill bit in the machine spindle. The DIN 6535-HA standard may specify specific requirements for the tolerances and quality of the cylindrical shank.

5. Solid carbide tool: Means the tool is made entirely of a hard and durable material such as carbide. Solid carbide tools are known for their strength and longevity, which translates into longer life and less need for replacement.

6. Coating on the cutting part: This is an additional layer of material covering the cutting part of a drill bit. These coatings can have various properties, such as reducing friction, increasing wear resistance, facilitating chip evacuation, or increasing tool life. The coating allows the drill bit to operate more effectively and efficiently, and to be more resistant to high loads and extreme machining conditions.

Here's how to match the drill bit to specific workpiece materials:

1. Non-alloy steels: the drill can be used to machine this type of steel.

2. Unalloyed and Alloyed Steels: The drill is suitable for machining both unalloyed steels and those containing some alloying additives.

3. Stainless & Acid-Resistant Steels: The drill can be used to machine stainless steels, including acid-resistant ones.

4. Stainless and Acid-Resistant Steels with Elevated Chromium and Nickel Content: This type of stainless steel often requires a more specialized tool, but depending on the specific processing conditions, this drill may be suitable.

5. Gray Cast Iron: The drill bit is suitable for machining this type of cast iron.

6. Spheroidal Cast Iron, Malleable Cast Iron: The drill can be used to machine these varieties of cast iron.

7. Titanium: Depending on the type of titanium, the drill bit may be suitable for processing it.

8. Aluminum, Copper: The drill bit can be used for machining aluminum and copper.

9. Aluminum Alloys, Copper Alloys: The drill bit can be suitable for machining aluminum and copper alloys.

10. Plastics*: The drill bit can be used to process various types of plastics.

However, it is important to remember that selecting the right tool for a particular material requires taking into account not only the type of material itself, but also its hardness, structure, as well as machining parameters such as tool speed and feed. It is advisable to consult a tool manufacturer or machining specialist to select the optimal tool for your application.

Specific References

No customer reviews for the moment.